Process Engineering

Process Engineering That Powers Every Stage of Production

Engineering safe, efficient, and flexible systems that drive performance.

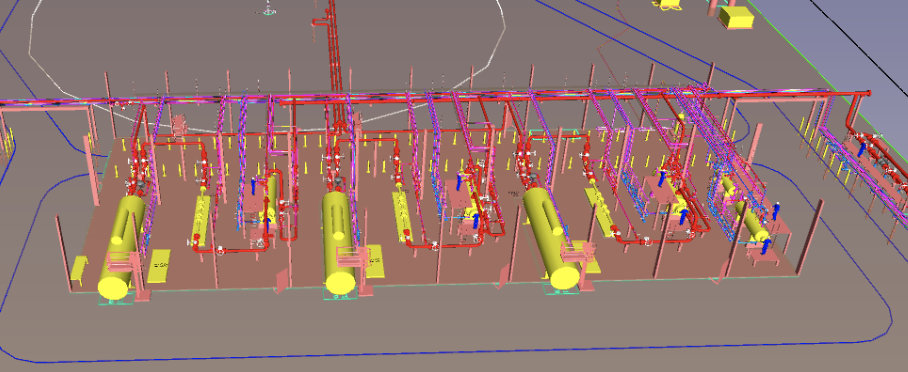

Halker’s Process Engineering team brings deep expertise in facility design, operations, and optimization. With experience spanning upstream and midstream sectors nationwide, our engineers understand the complete process lifecycle, from early design and simulation through detailed engineering, commissioning, and operations support. Our approach emphasizes precision, safety, and innovation, ensuring every system is engineered to meet project goals, regulatory requirements, and evolving energy demands. From gas processing and dehydration to cryogenic and solvent-based separation systems, we deliver tailored solutions built on technical excellence and real-world insight.

Our team delivers tailored, fit-for-purpose solutions across upstream, SWD and transmix facilities, gas processing, PSV studies, PSM/PHA documentation & support, OOOOb compliance and environmental reporting.

To support our engineering excellence, Halker utilizes advanced modeling and simulation tools to evaluate, optimize, and validate system performance. Our team leverages industry-standard platforms such as Aspen HYSYS, Honeywell UniSim, SLB Symmetry, Promax, AFT Fathom and Arrow, iPRISM, and so much more!

Key Capabilities

Our process engineers provide the foundation for efficient, compliant, and cost-effective operations and construction, integrating with every discipline to deliver systems that perform in the field, not just on paper.

Facility Design & Optimization

Comprehensive design and simulation of upstream and midstream facilities to improve compliance, performance, and safety

Gas Processing & Booster Stations

Expertise in dehydration, cryogenic recovery, and compression tailored to each project’s flow conditions & capacity.

Carbon Capture & Environmental Integration

Developing process strategies that incorporate carbon sequestration, emissions reduction, and sustainability goals into new & existing operations.

Commissioning & Operational Support

End-to-end guidance from initial modeling to start-up, including troubleshooting, testing, and PSM compliance support to ensure long-term reliability.

Why Our Clients Trust Halker

Proven Experience Across the Spectrum

Over two decades of experience designing process systems for oil, gas, and energy facilities ensures our clients benefit from proven, field-tested expertise.

Seamless, Multidisciplinary Collaboration

We tailor teams of mechanical, civil, electrical, and automation engineers to create cohesive, efficient systems that meet every technical standard.

Fit-for-Purpose, Future-Ready Design

Every Halker process solution is built with flexibility and is adaptable to shifting production goals, regulations, and technologies.

Our Innovative Projects in Action

Helium Plant Process Study

A client required a detailed process engineering study to evaluate the technical and economic feasibility of developing a new helium

Midstream Plant Expansion

The client required comprehensive engineering and design support to execute a series of upgrades at an existing natural gas processing

Helium Plant Engineering & Design

The client required a full engineering and design solution for a new helium processing facility capable of handling complex gas

Ready to Engineer

Your Next Success?

Work with a team that listens, collaborates, and turns your vision into practical, innovative solutions.