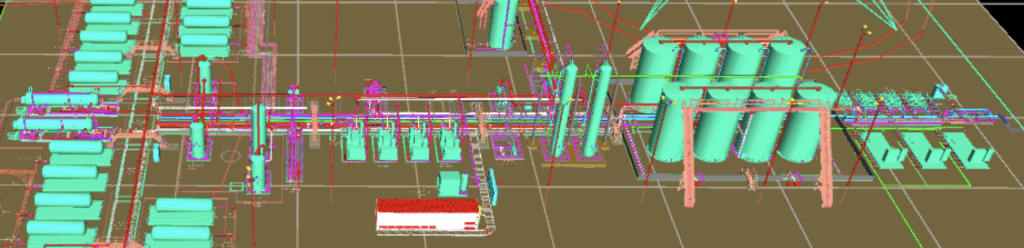

Permian Basin CTB-Facility Design Program

The client required a multi-facility program to design and construct a series of centralized tank batteries (CTBs) to serve multiple well pads while maintaining consistency, efficiency, and regulatory compliance.

CTB-Facility Design Program

The client required detailed engineering and design for multiple centralized tank battery (CTB) and well pad facilities in New Mexico. Each site needed to balance standardization with customization—leveraging proven designs while adapting to site-specific production, layout, and regulatory requirements.

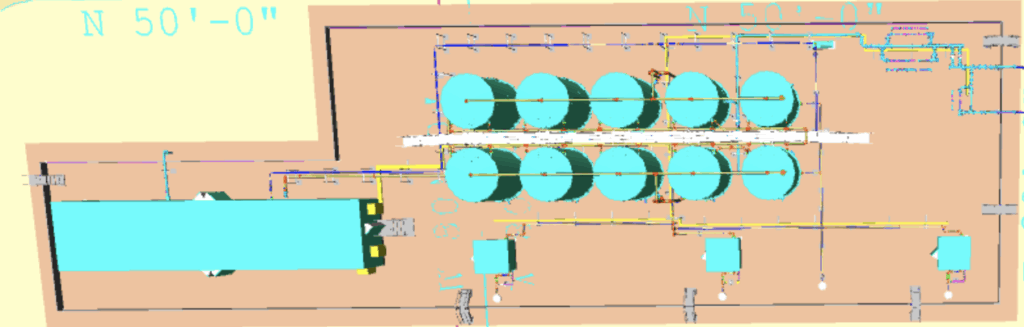

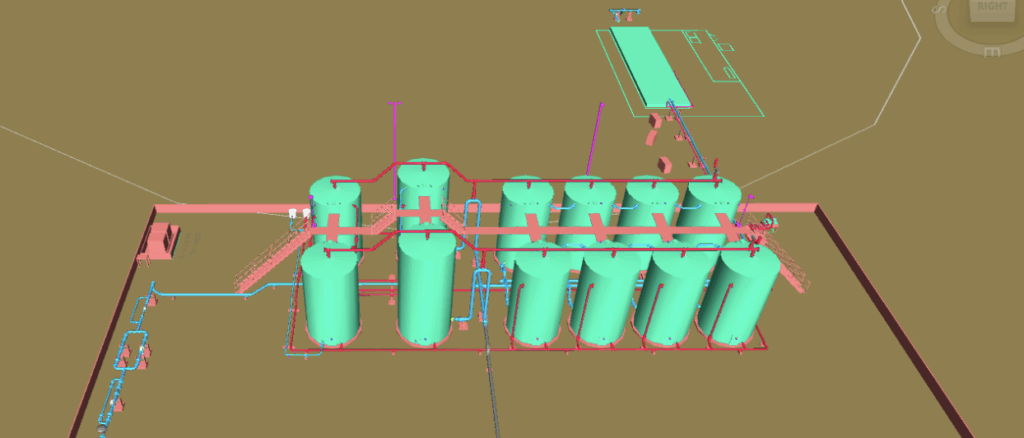

SWD Engineering and Design

The client required a comprehensive engineering and design solution for a new saltwater disposal (SWD) facility that aligned with established program standards and specifications. The project needed to maintain consistency with the client’s existing design framework while integrating updated electrical, instrumentation, and control (EI&C) standards.

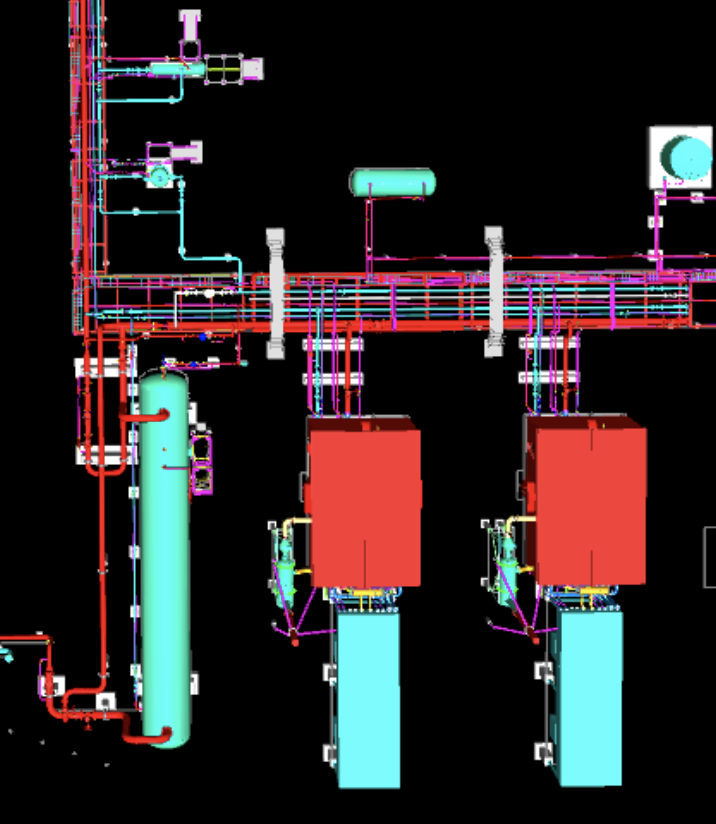

Midstream Plant Expansion

The client required comprehensive engineering and design support to execute a series of upgrades at an existing natural gas processing facility. The project involved integrating new compression and heating systems into an established plant layout while maintaining operational continuity and meeting modern safety, electrical, and structural standards.

10,000-20,000 BBLPD SWD Engineering and Design

The client required a fully integrated engineering and design solution for a new 10,000 BBLPD saltwater disposal (SWD) facility, with future expansion capacity to 20,000 BBLPD. The project demanded coordination across multiple engineering disciplines—process, mechanical, structural, electrical, and instrumentation & controls—to ensure consistency, compliance, and scalability.

Greenfield Compressor Station Engineering and Design

The client required full engineering, design, and project management support for the development of a new greenfield gas gathering compressor station in Utah. The facility needed to accommodate immediate production demands while maintaining flexibility for future expansion from two to four compressor units.

Conversion of Biomass Waste to Jet Fuel

Our client owns a process to convert carbon containing feedstock into syngas. This specific technology was selected for application at a Biofuels project in Lakeview, Oregon, which was designed to convert waste woody biomass into renewable jet and diesel fuels.

Full-Field Development

Process Engineering, Project Engineering, Equipment Design, Civil/Structural Design, Electrical Design, Instrumentation Design