OOOOc Compliance Walkdowns

The client required a comprehensive assessment of over 80 production facilities to evaluate compliance with proposed EPA 40 CFR 60 Subpart OOOOc methane emissions standards. The project demanded rapid field data collection and engineering analysis to identify necessary equipment modifications, potential retrofit needs, and associated implementation costs.

Multi-Site Midstream Tie In Project

The client required a comprehensive engineering and design solution for a complex, multi-site pipeline tie-in project involving several interconnected valve and meter sites. The project demanded precise coordination across multiple facilities, including integration of new and existing pipeline segments of varying diameters, materials, and configurations.

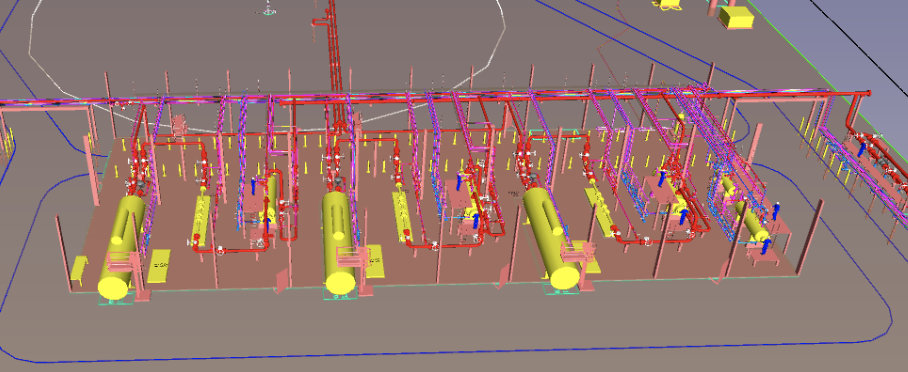

Midstream Plant Operational Efficiency Upgrades

The client required critical piping and equipment modifications to improve operational efficiency and system reliability within an existing process unit. The project needed to address issues related to a pocketed bypass line and inefficient drainage while maintaining compliance with the client’s design and safety standards.

Meter Skid Tie In Project

The client required a detailed engineering and design solution to integrate multiple new meter skids—a main meter skid, a buy-back meter skid, and a vapor recovery unit (VRU) meter skid—into an existing pipeline system via a hot-tap connection.

Helium Plant Process Study

A client required a detailed process engineering study to evaluate the technical and economic feasibility of developing a new helium recovery facility. The project involved determining the optimal method for extracting marketable helium from a complex produced gas stream containing acid gases and other contaminants.

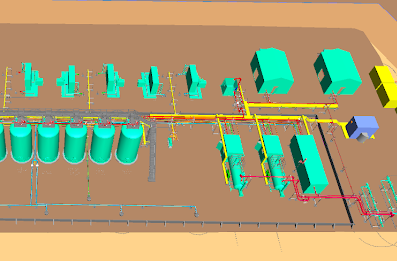

Permian Basin CTB-Facility Design Program

The client required a multi-facility program to design and construct a series of centralized tank batteries (CTBs) to serve multiple well pads while maintaining consistency, efficiency, and regulatory compliance.

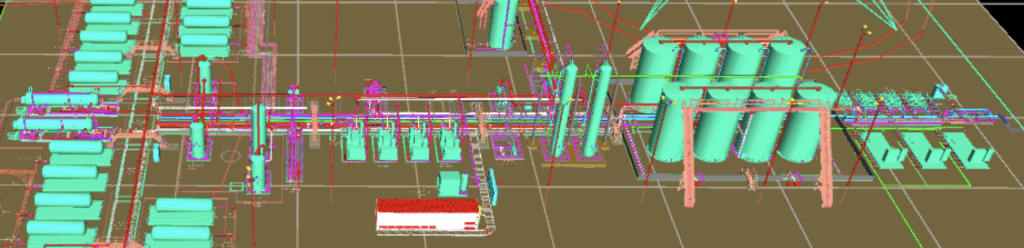

Bakken Basin CTB Facility Design Program

The client required an Owner’s Engineer to support the design and implementation of new centralized tank battery (CTB) facilities in compliance with evolving federal regulations, including 40 CFR 60 Subparts OOOOa and OOOOb. The program involved simultaneous upgrades across more than 150 sites, demanding a coordinated, multi-discipline engineering approach that balanced regulatory compliance, constructability, and operational efficiency.

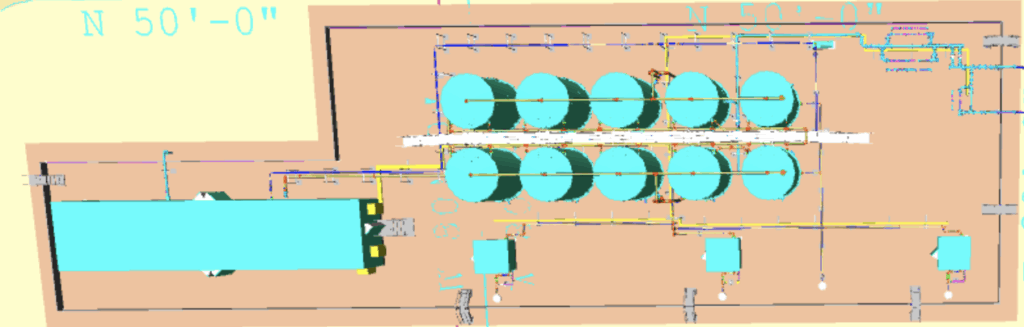

CTB-Facility Design Program

The client required detailed engineering and design for multiple centralized tank battery (CTB) and well pad facilities in New Mexico. Each site needed to balance standardization with customization—leveraging proven designs while adapting to site-specific production, layout, and regulatory requirements.

SWD Engineering and Design

The client required a comprehensive engineering and design solution for a new saltwater disposal (SWD) facility that aligned with established program standards and specifications. The project needed to maintain consistency with the client’s existing design framework while integrating updated electrical, instrumentation, and control (EI&C) standards.

SWD Commissioning and Construction Support

The client required comprehensive commissioning and startup support for a newly constructed saltwater disposal (SWD) facility. The project assumed mechanical completion by the construction contractor, but successful commissioning depended on coordinated system verification, safety assurance, and readiness documentation across multiple disciplines.