Permian Basin OOOOb Compliance Walk Downs

The client required accurate and verifiable greenhouse gas (GHG) emissions data for existing facilities across the Permian Basin. Many sites contained incomplete or outdated equipment records within their asset management system, making it essential to validate and update information for all Tier 1 equipment.

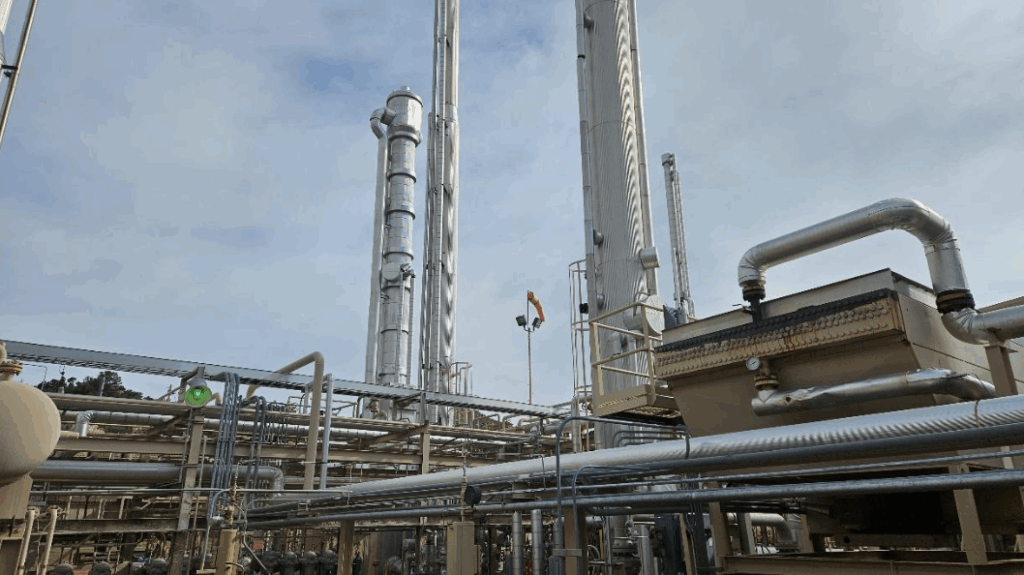

Midstream Plant Expansion

The client required comprehensive engineering and design support to execute a series of upgrades at an existing natural gas processing facility. The project involved integrating new compression and heating systems into an established plant layout while maintaining operational continuity and meeting modern safety, electrical, and structural standards.

Helium Plant Engineering & Design

The client required a full engineering and design solution for a new helium processing facility capable of handling complex gas treatment and extraction operations. The project demanded seamless coordination among multiple engineering disciplines and the successful integration of a third-party proprietary helium extraction system into the overall process.

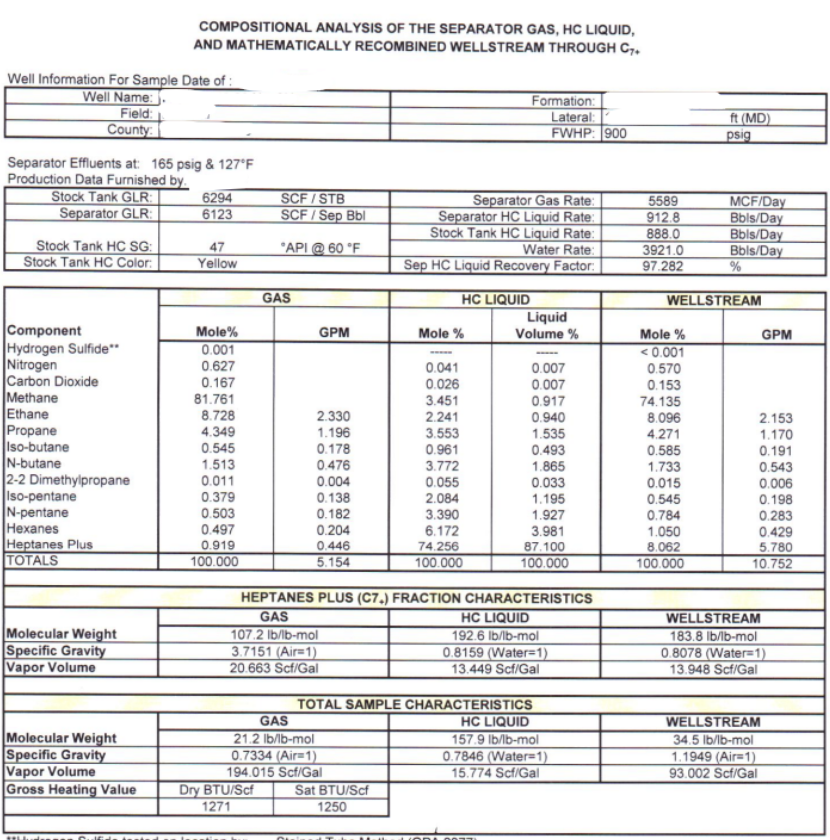

Gas Plant Optimization Study

The client required a comprehensive evaluation and process optimization effort to improve the accuracy of an existing gas processing plant model and identify opportunities for operational improvement. The existing process model contained outdated and incomplete information, limiting its reliability for performance analysis and decision-making.

Engineering Site Assessments

The client required detailed engineering assessments for twenty well pad facilities in the Permian Basin to verify compliance with federal emissions regulations, specifically 40 CFR 60 Subpart OOOOb. The primary challenge was to ensure that all process equipment and vapor control systems were properly designed, configured, and operated to capture and control emissions effectively.

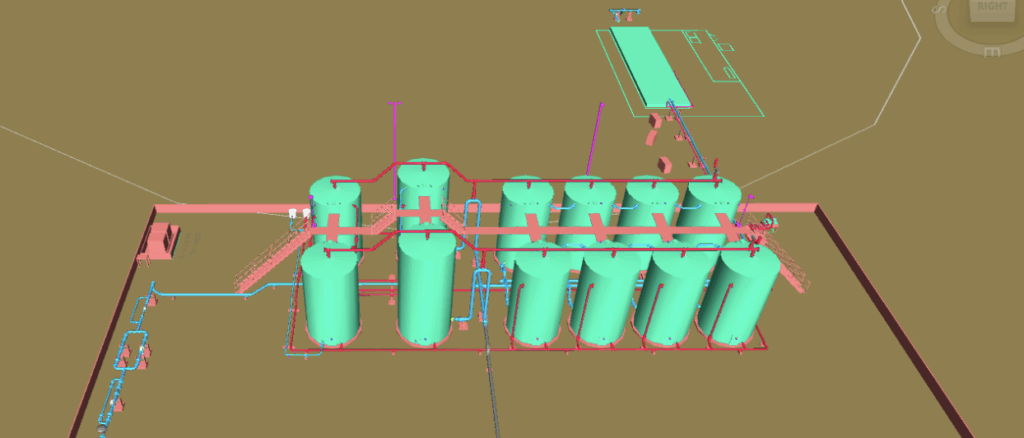

10,000-20,000 BBLPD SWD Engineering and Design

The client required a fully integrated engineering and design solution for a new 10,000 BBLPD saltwater disposal (SWD) facility, with future expansion capacity to 20,000 BBLPD. The project demanded coordination across multiple engineering disciplines—process, mechanical, structural, electrical, and instrumentation & controls—to ensure consistency, compliance, and scalability.

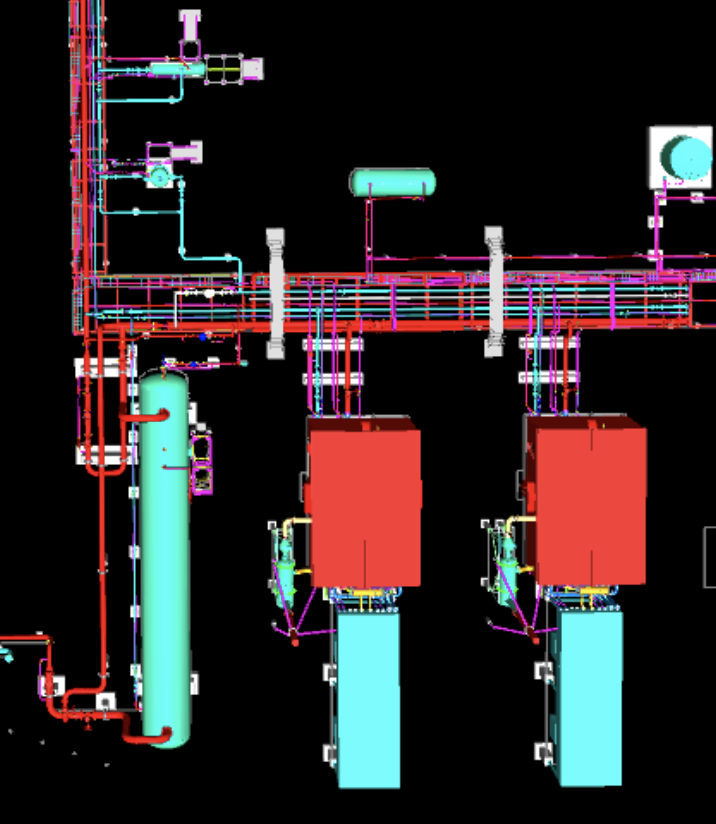

Greenfield Compressor Station Engineering and Design

The client required full engineering, design, and project management support for the development of a new greenfield gas gathering compressor station in Utah. The facility needed to accommodate immediate production demands while maintaining flexibility for future expansion from two to four compressor units.

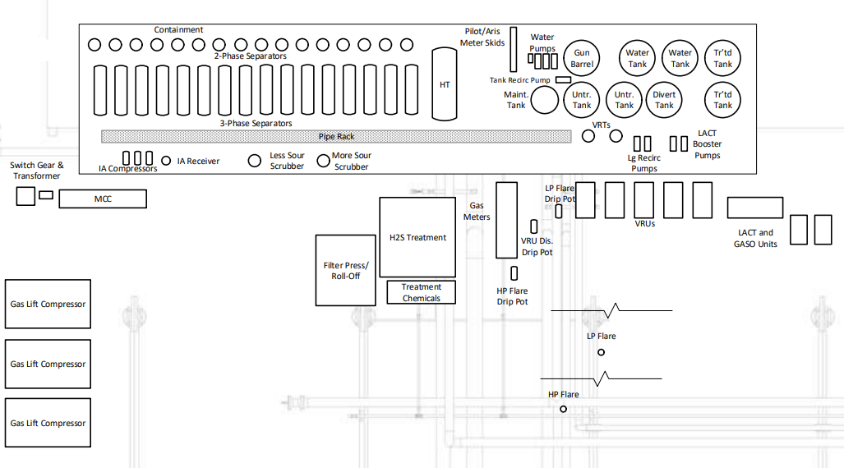

Bulk Test Conversion for Sour Service CTB Facility

The client required the conversion of existing Central Tank Battery (CTB) facilities into a large-scale sour service production site capable of safely managing high hydrogen sulfide (H₂S) concentrations. The project demanded a comprehensive redesign to accommodate new process equipment, integrate sour gas treatment systems, and ensure full compliance with applicable safety and regulatory standards.

Salt Water Disposal Facility & Infrastructure

Halker was tasked with coordinating the design of the Water Gathering Infrastructure with the contractors responsible for the Oil & Gas Infrastructure and Electrical Grid.

Sour Gas CTB-Facility Design

The client required a new centralized tank battery (CTB) in the Permian Basin capable of safely handling production from multiple wells with elevated hydrogen sulfide (H₂S) concentrations. The project demanded a design that would ensure compliance with all applicable NACE sour service standards while maintaining efficient operations and accommodating future development.