Engineering Services Projects

OOOOc Compliance Walkdowns

The client required a comprehensive assessment of over 80 production facilities to evaluate compliance with proposed EPA 40 CFR 60

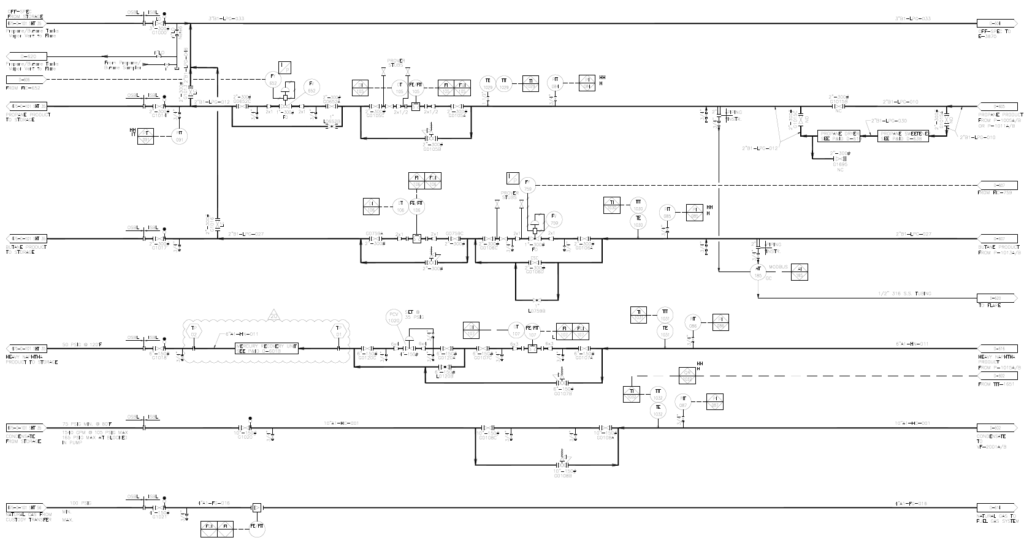

Multi-Site Midstream Tie In Project

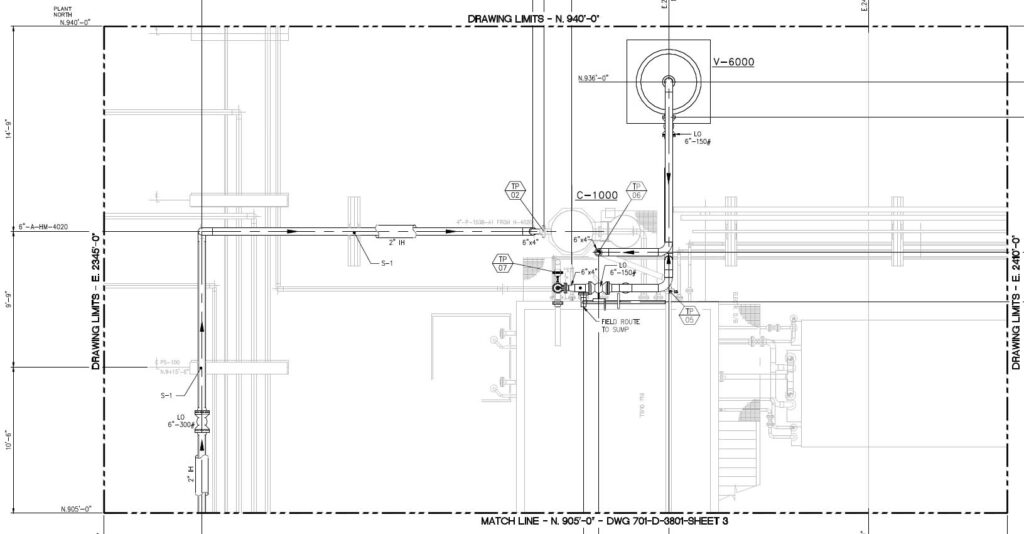

The client required a comprehensive engineering and design solution for a complex, multi-site pipeline tie-in project involving several interconnected valve

Midstream Plant Operational Efficiency Upgrades

The client required critical piping and equipment modifications to improve operational efficiency and system reliability within an existing process unit.

Meter Skid Tie In Project

The client required a detailed engineering and design solution to integrate multiple new meter skids—a main meter skid, a buy-back

Helium Plant Process Study

A client required a detailed process engineering study to evaluate the technical and economic feasibility of developing a new helium

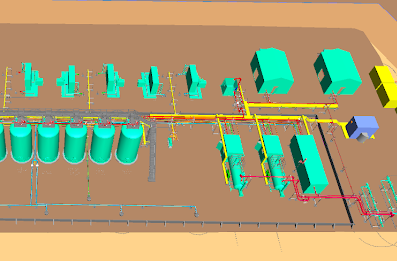

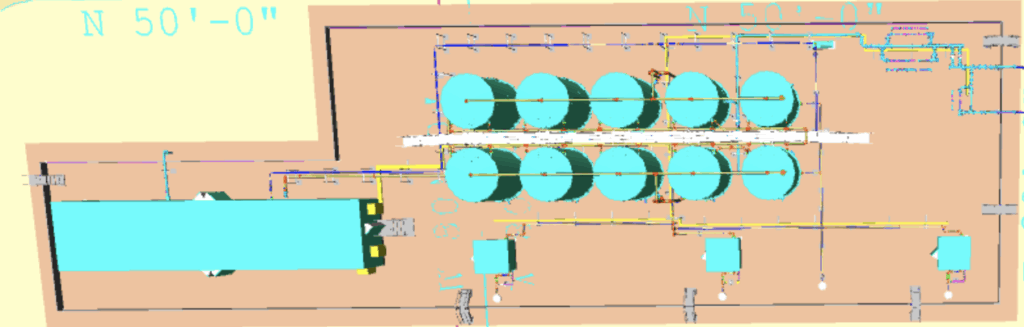

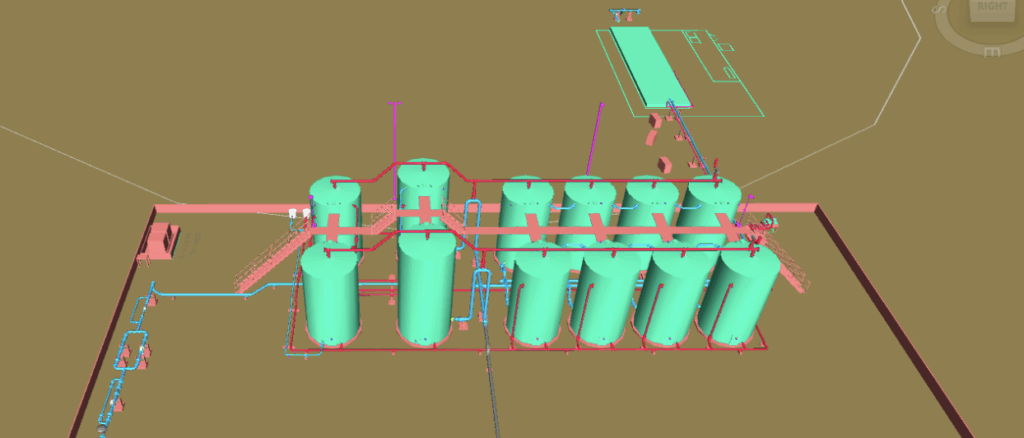

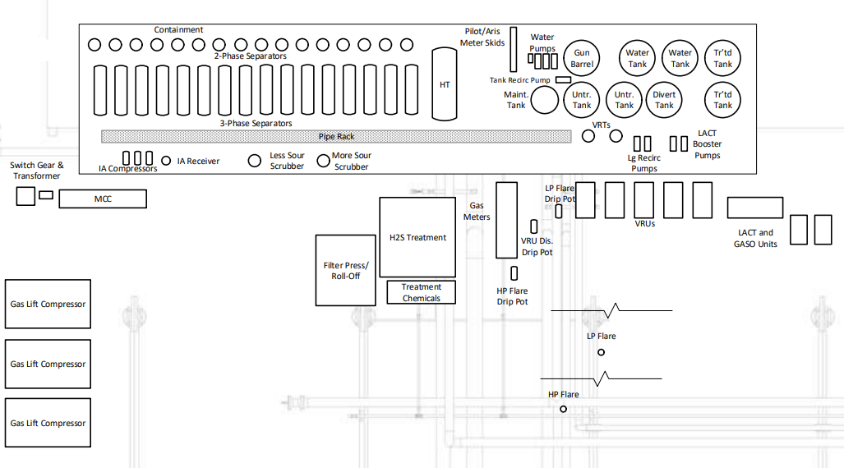

Permian Basin CTB-Facility Design Program

The client required a multi-facility program to design and construct a series of centralized tank batteries (CTBs) to serve multiple

Bakken Basin CTB Facility Design Program

The client required an Owner’s Engineer to support the design and implementation of new centralized tank battery (CTB) facilities in

CTB-Facility Design Program

The client required detailed engineering and design for multiple centralized tank battery (CTB) and well pad facilities in New Mexico.

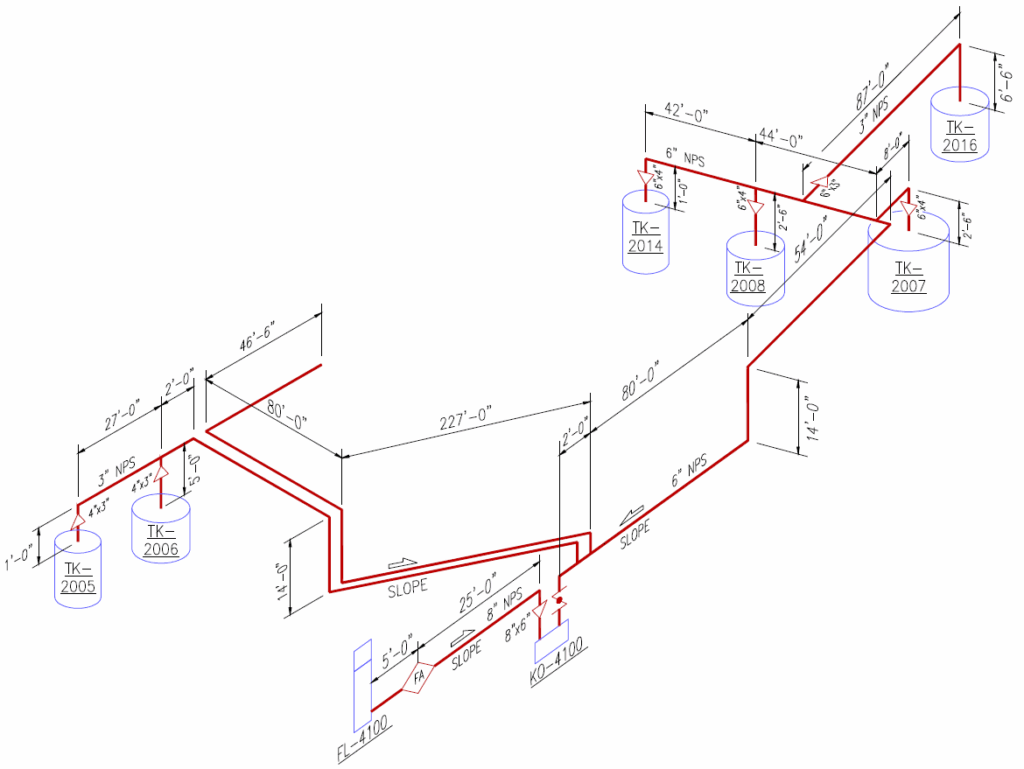

SWD Engineering and Design

The client required a comprehensive engineering and design solution for a new saltwater disposal (SWD) facility that aligned with established

SWD Commissioning and Construction Support

The client required comprehensive commissioning and startup support for a newly constructed saltwater disposal (SWD) facility. The project assumed mechanical

Permian Basin OOOOb Compliance Walk Downs

The client required accurate and verifiable greenhouse gas (GHG) emissions data for existing facilities across the Permian Basin. Many sites

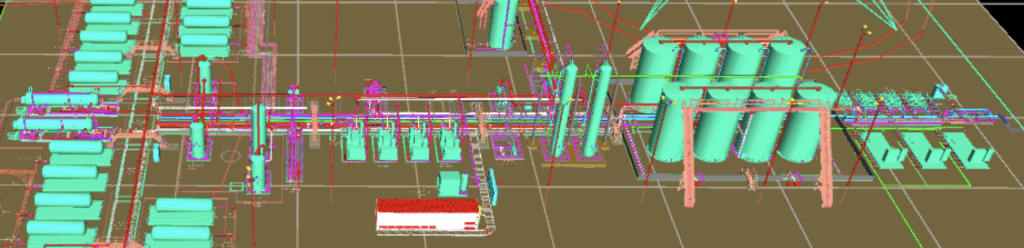

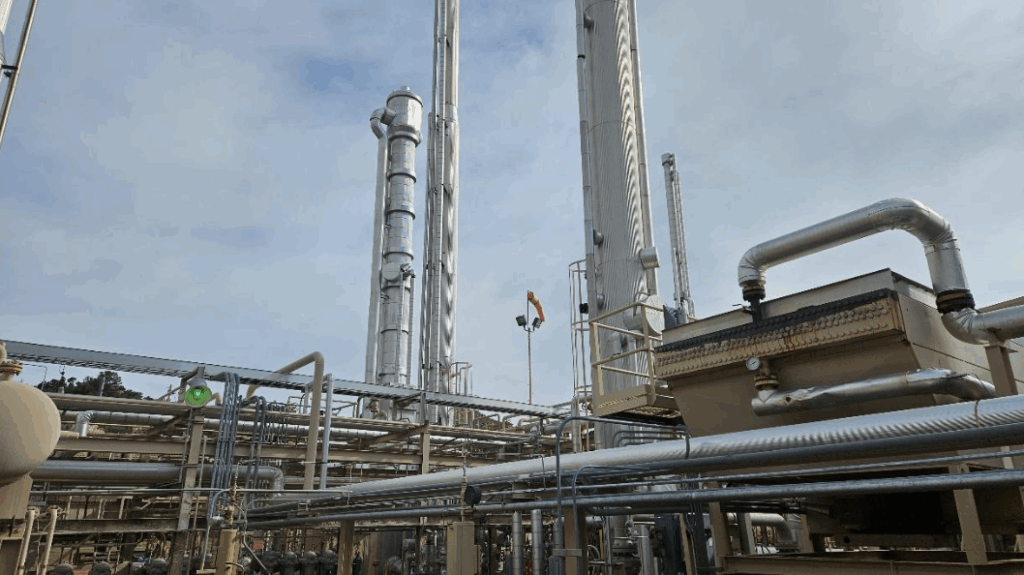

Midstream Plant Expansion

The client required comprehensive engineering and design support to execute a series of upgrades at an existing natural gas processing

Helium Plant Engineering & Design

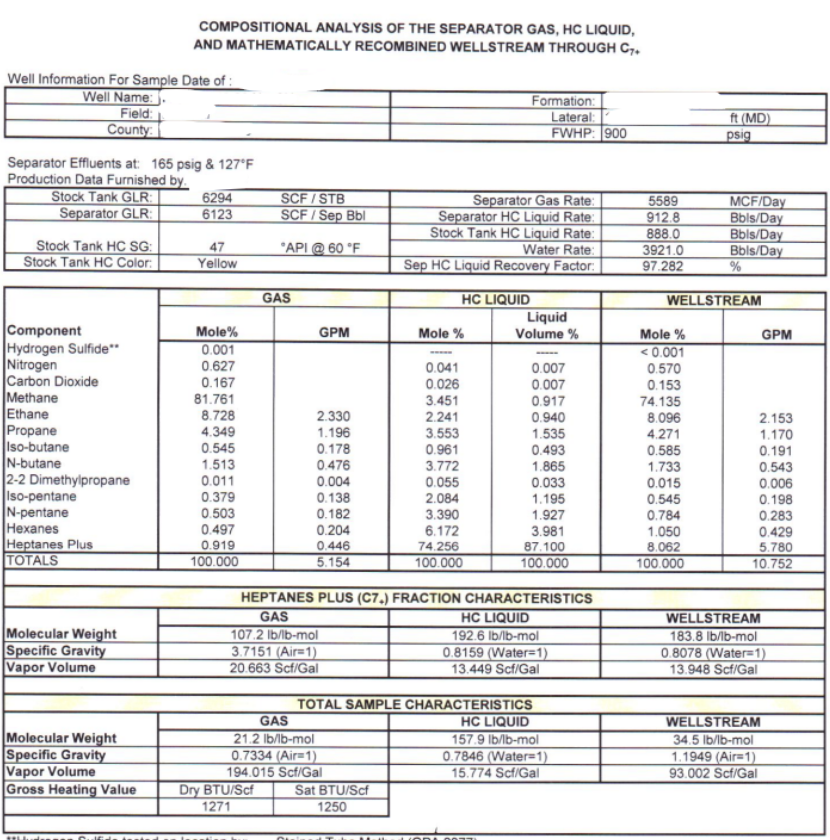

The client required a full engineering and design solution for a new helium processing facility capable of handling complex gas

Gas Plant Optimization Study

The client required a comprehensive evaluation and process optimization effort to improve the accuracy of an existing gas processing plant

Engineering Site Assessments

The client required detailed engineering assessments for twenty well pad facilities in the Permian Basin to verify compliance with federal

Anadarko Basin OOOOb Compliance Walk Downs

The client required accurate and verifiable greenhouse gas (GHG) emissions data for existing facilities across the Permian Basin. Many sites

10,000-20,000 BBLPD SWD Engineering and Design

The client required a fully integrated engineering and design solution for a new 10,000 BBLPD saltwater disposal (SWD) facility, with

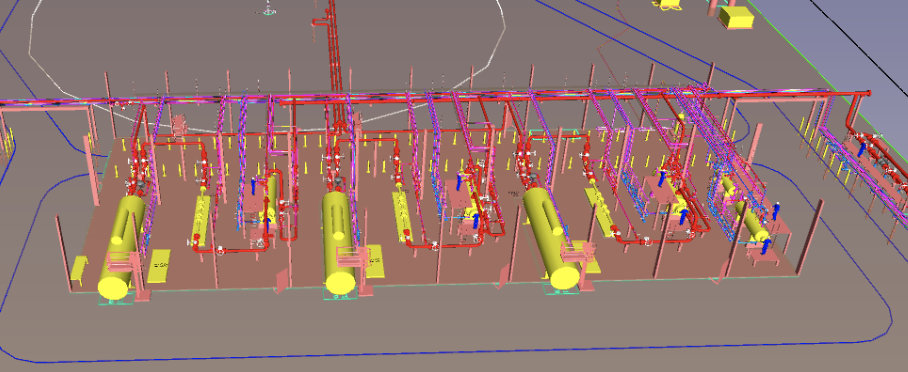

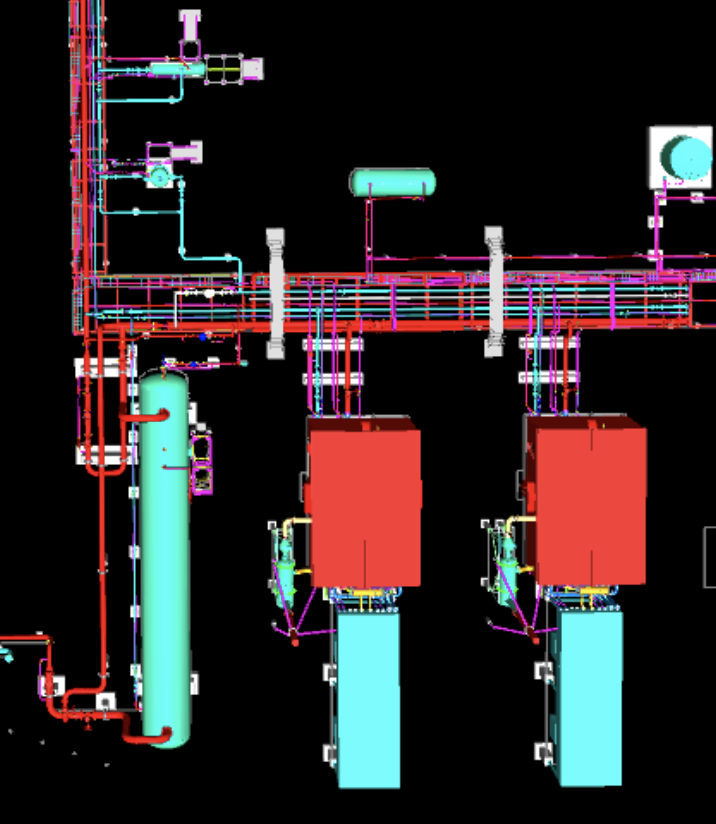

Greenfield Compressor Station Engineering and Design

The client required full engineering, design, and project management support for the development of a new greenfield gas gathering compressor

Bulk Test Conversion for Sour Service CTB Facility

The client required the conversion of existing Central Tank Battery (CTB) facilities into a large-scale sour service production site capable

Salt Water Disposal Facility & Infrastructure

Halker was tasked with coordinating the design of the Water Gathering Infrastructure with the contractors responsible for the Oil &

Sour Gas CTB-Facility Design

The client required a new centralized tank battery (CTB) in the Permian Basin capable of safely handling production from multiple

Water Injection

A Halker Client was in need of water injection facilities that could meet the needs of their water flood at

Mercury Removal & Bonus Target

In 2020, a Midstream distribution company (“Client”), with nearly 10,000 miles of pipelines and over 50 terminals for refined petroleum

Conversion of Biomass Waste to Jet Fuel

Our client owns a process to convert carbon containing feedstock into syngas. This specific technology was selected for application at

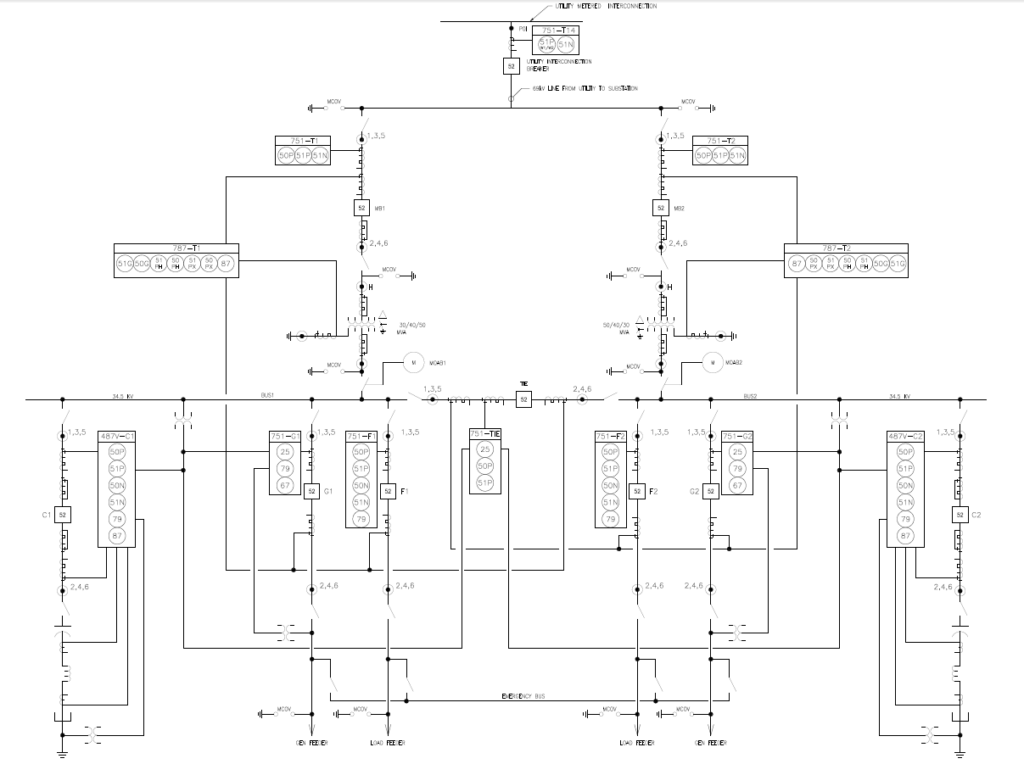

Power Distribution Field Inspection & Evaluation

This client reached out to Halker because they were having power reliability problems with their current utility interconnection and power

Fugitive Emissions Study

The client needed to reduce or eliminate fugitive emissions from over 50 existing upstream production facilities in order to meet

Power Infrastructure Feasibility Study

his client approached Halker to perform a feasibility study and preliminary design for the required power infrastructure to supply around

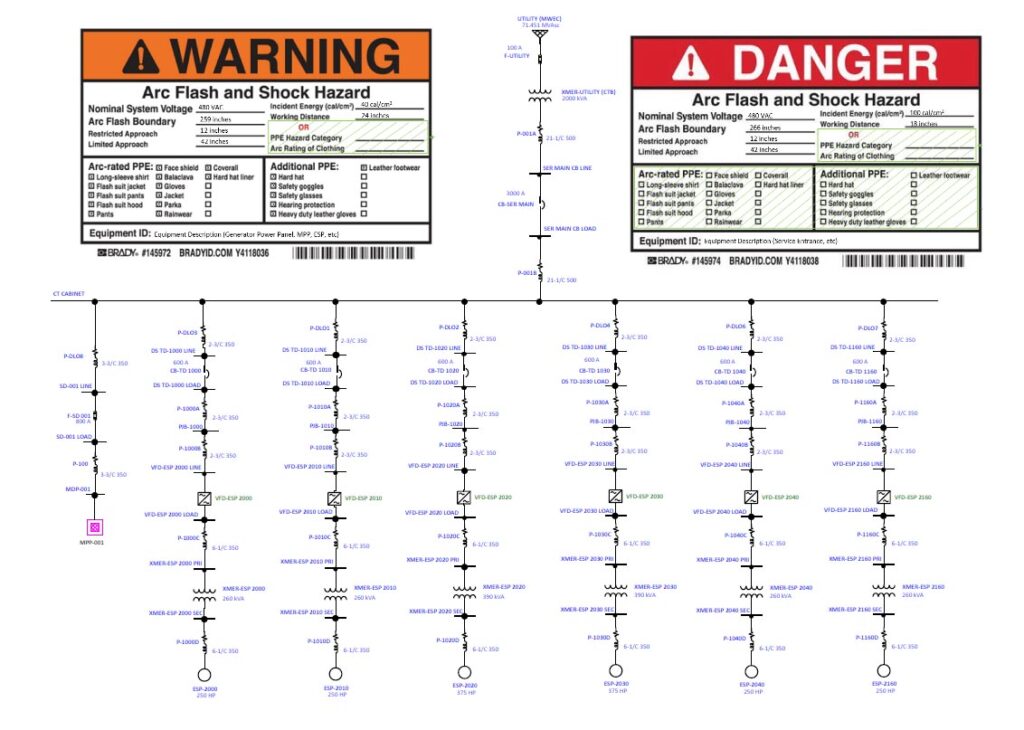

Electrical System Studies

The client reached out to Halker to perform electrical studies on both existing and new-built assets. Through the studies, Halker

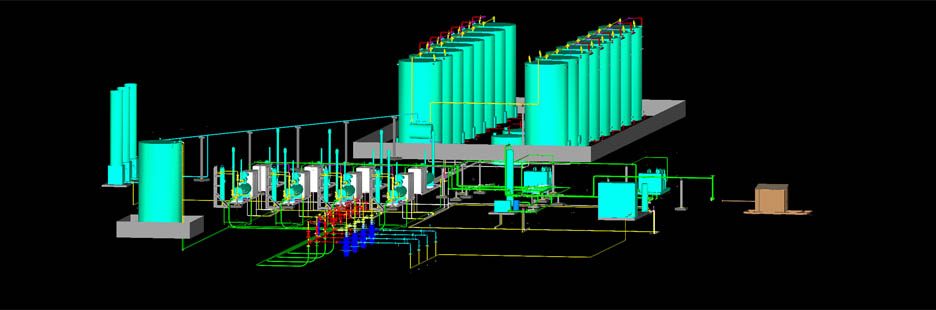

Full-Field Development

Process Engineering, Project Engineering, Equipment Design, Civil/Structural Design, Electrical Design, Instrumentation Design

Hydraulic Modeling Study

The client requested hydraulic modeling and simulation of existing gas and water pipeline networks in order to assess wellhead pressures

Gathering and Pipeflow Modeling

A Texas based company looked to longtime partner Halker Consulting, to create a flow model of the design for an

Flare Study Project

As federal regulations continue to change and become more stringent, Oil and Gas companies must conform to these guidelines in

Flare System Retrofit

In 2015, a publicly traded pipeline transport company (“Client”), approached Halker Consulting (“Halker”) to evaluate a recently acquired gas plant.

Frac Tower Return to Service

In 2015, a Midstream distribution company (“Client”), with terminals spanning across the United States, approached Halker

Consulting LLC (“Halker”)

Coal Additive System

The client had developed a process to reduce emissions at a coal power plant in Arizona, but needed assistance with

Gas Compressor Station

As with many Halker customers, this Texas based organization was challenged with a lack of internal engineering resources to match

Three Phase Separator

This experienced customer came to Halker Consulting with a need to design and engineer a three phase separator for multiple

Facilities Conversion to Meet Evolving Needs

Maybe they were not producing enough oil and gas previously to justify the infrastructure investment, or maybe the wells in

Strategic Field Development

The widespread adoption of offshore-born approaches by surface well operators in the last several years has been game changing for

Central Processing Facilities

As the American oil and gas industry moves away from single-well, vertical drilling techniques and embraces the opportunities available via

Multi-Well Site Facilities

The paradigm of American energy is undergoing a massive transformation. In addition to the evolution of renewable energy technologies, and