Water Injection

A Halker Client was in need of water injection facilities that could meet the needs of their water flood at a constant pressure over time to aid in the recovery of their oil.

Mercury Removal & Bonus Target

In 2020, a Midstream distribution company (“Client”), with nearly 10,000 miles of pipelines and over 50 terminals for refined petroleum products, approached Halker Consulting (”Halker”) for a phased project at their condensate splitter facility to increase profitability.

Conversion of Biomass Waste to Jet Fuel

Our client owns a process to convert carbon containing feedstock into syngas. This specific technology was selected for application at a Biofuels project in Lakeview, Oregon, which was designed to convert waste woody biomass into renewable jet and diesel fuels.

Fugitive Emissions Study

The client needed to reduce or eliminate fugitive emissions from over 50 existing upstream production facilities in order to meet 40 CFR 60 OOOOa requirements with an aggressive schedule. The fugitive emission sources were both oil and water storage tanks on site.

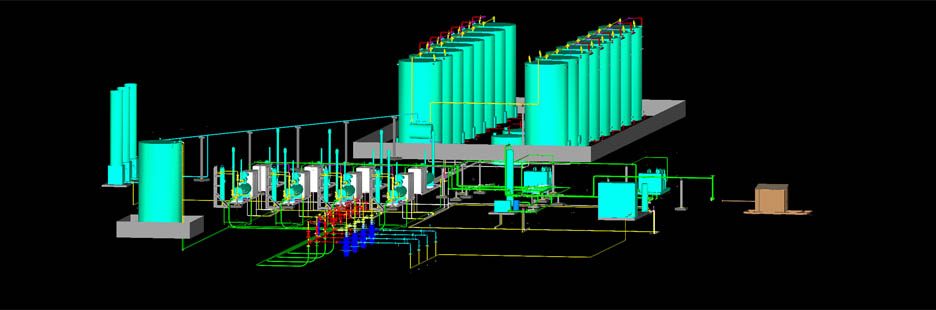

Full-Field Development

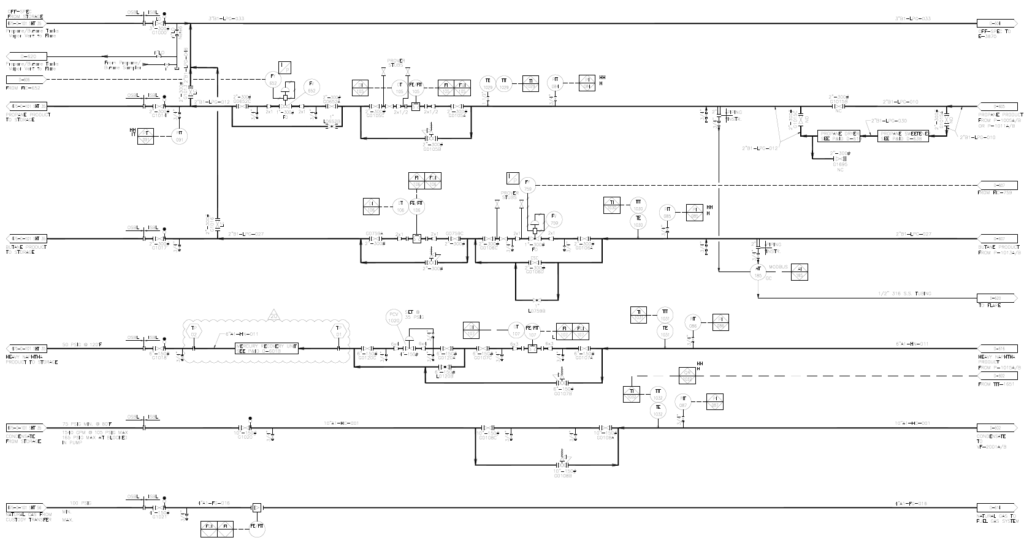

Process Engineering, Project Engineering, Equipment Design, Civil/Structural Design, Electrical Design, Instrumentation Design

Hydraulic Modeling Study

The client requested hydraulic modeling and simulation of existing gas and water pipeline networks in order to assess wellhead pressures and provide recommendations on infrastructure additions and operational changes to mitigate bottlenecks in the pipeline network.

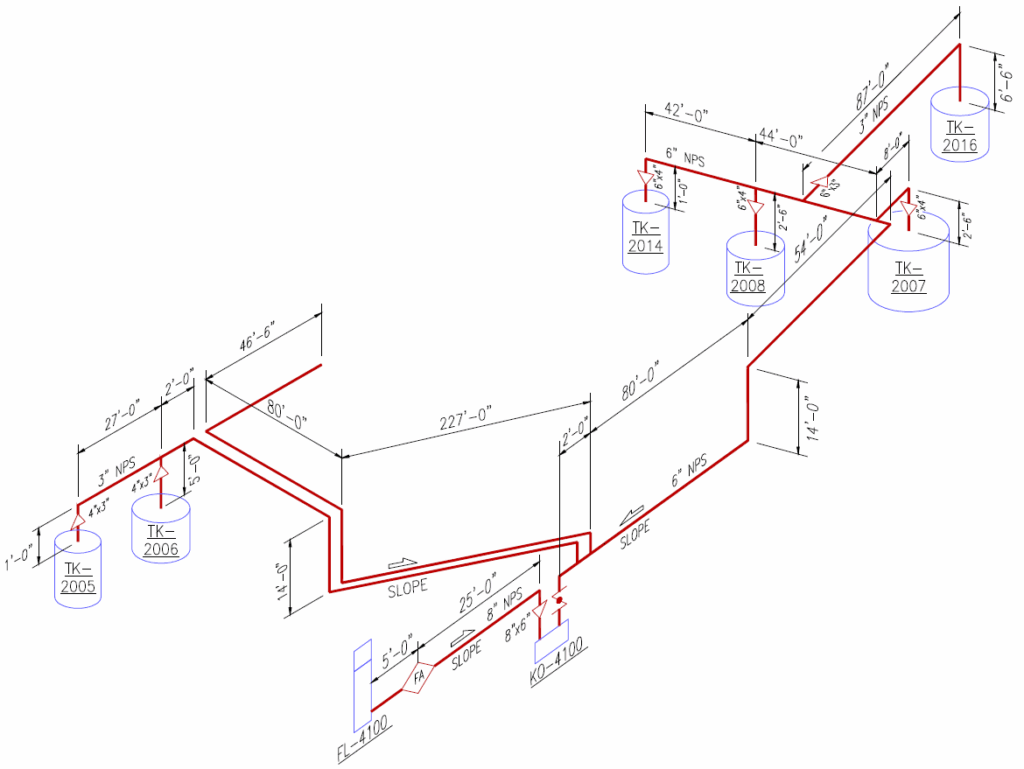

Gathering and Pipeflow Modeling

A Texas based company looked to longtime partner Halker Consulting, to create a flow model of the design for an upstream production site that would hand off to a traditional midstream conveyance provider.

Flare Study Project

As federal regulations continue to change and become more stringent, Oil and Gas companies must conform to these guidelines in order to stay compliant.

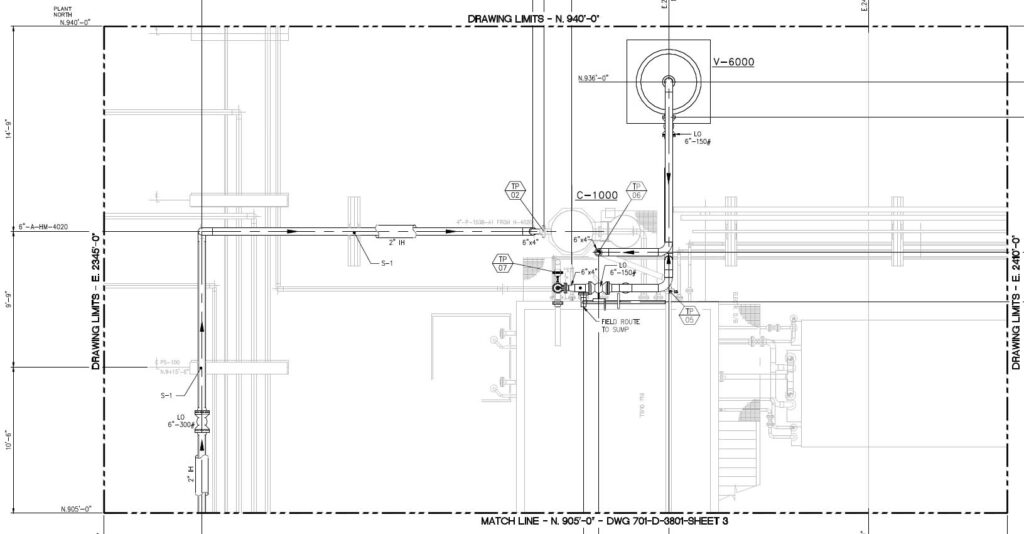

Flare System Retrofit

In 2015, a publicly traded pipeline transport company (“Client”), approached Halker Consulting (“Halker”) to evaluate a recently acquired gas plant.

Frac Tower Return to Service

In 2015, a Midstream distribution company (“Client”), with terminals spanning across the United States, approached Halker

Consulting LLC (“Halker”) for help placing a fractionator back into service at one of their Texas terminals.